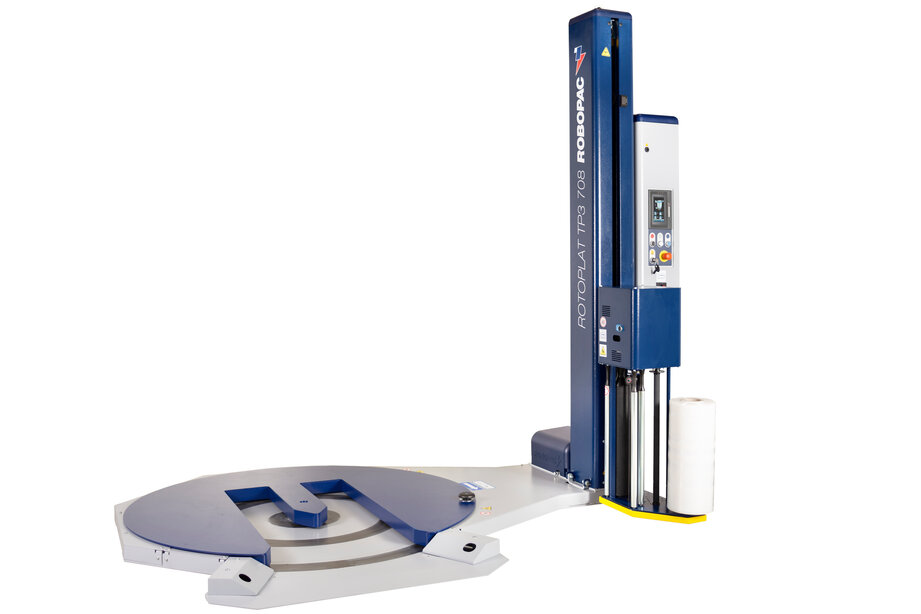

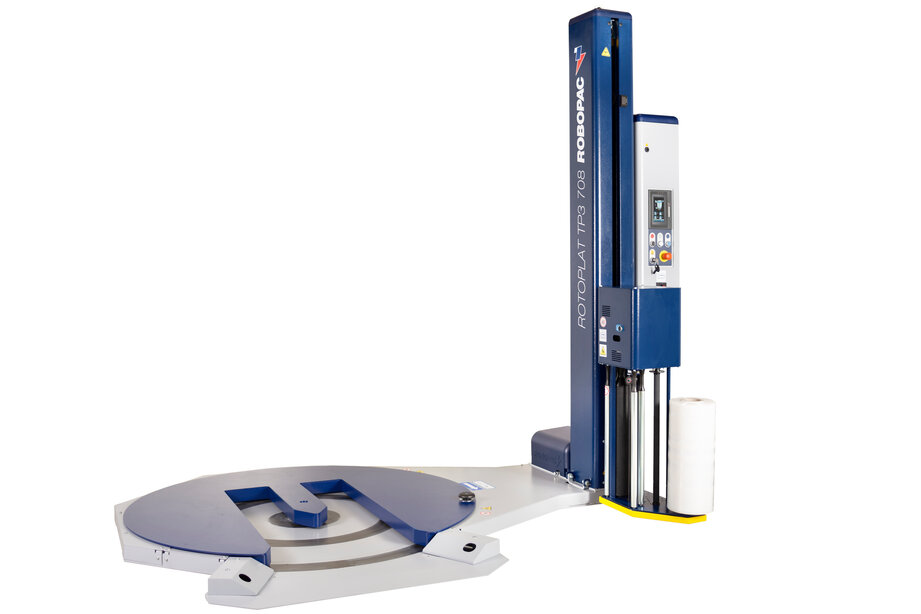

Rotoplat TP3 Turntable wrapping machines with shaped plate for pallet jack loading

Rotoplat TP3 is a turntable wrapping machine for wrapping products with stretch film in vertical. Thanks to the TP3 turntable, designed for loading with hand pallet trucks, it is possible to change the load side by choosing 3 different configurations according to the customer's needs.

close

Available Models

Rotoplat TP3

Rotoplat TP3 is a turntable wrapping machine for wrapping products with stretch film in vertical. Thanks to the TP3 turntable, designed for loading with hand pallet trucks, it is possible to change the load side by choosing 3 different configurations according to the customer's needs.

BENEFITS

- USABILITY designed for loading with hand pallet trucks

- FLEXIBILITY thanks to the new base, it can be installed in 3 different loading lines

- SAFETY equipped with new ramp with safety photocells

- EASE OF LOADING new V shape for easy entry of the pallet truck

- STURDINESS greater solidity thanks to the new rolling system of the plate

Rotoplat Inox TP3

Stainless steel wrapping turntable for use in the foodstuffs field, and outside place with high humidity.

Thanks to the TP3 turntable, designed for loading with hand pallet trucks, it is possible to change the load side by choosing 3 different configurations according to the customer's needs.

BENEFITS:

- The perfect solution for companies working in the food industry

- Greater resistance to oxidation and corrosion

- Designed for loading with hand pallet trucks

- Thanks to the new base, it can be installed in 3 different way

- Stainless steel material for environments with a high humidity level

- Possible version for temperatures up to -30°C

product benefits

USABILITY

Designed for loading with hand pallet trucks

FLEXIBILITY

Thanks to the new base, it can be installed in 3 different loading lines

SAFETY

Equipped with new ramp with safety photocells

EASE OF LOADING

New V shape for easy entry of the pallet truck

STURDINESS

Greater solidity thanks to the new rolling system of the plate

DETAILS

FR carriage

Film carriage with electromagnetic powder brake on return roller, stretch tension adjustable from control panel.

PDS carriage

PDS Carriage with dual pre-stretch rollers controlled via the control panel. Pre-stretch system is fixed at 250%. “Stretch Control” control activates the electromagnetic clutch positioned on the first roller.

PVS carriage

The PVS Carriage with powered stretch system controlled by two independent motors. Stretch ratio adjustable from panel board from 150% up to 400%. Force to the load controlled by patented electronic device and adjustable from panel board.

7'' TOUCH SCREEN CONTROL PANEL

The control panel is the brain of Rotoplat, here lies the heart of the machine and technology Robopac ie Cube Technology.

overview

Discover more on our app Robopac HMI

Try the Rotoplat, Masteplat Plus & Robot S7 user friendly control panel on your devices.

TP3 turntable

option & data sheet

R-Connect

Innovation and connection for customer service: the tranquillity of maximum productivity as a result of constant monitoring of proper machine operation.

Powerful, plug & play and user friendly, R-Connect is a “turnkey” system for the end-user: the main advantage is total “peace of mind”, which is absolute tranquillity regarding machine operation, which includes production performance verification and optimisation of all management costs.

In fact, the system minimises machine downtime and manages maintenance operations better, also providing an immediate troubleshooting procedure, until the full and remote upgrade of the machine’s management software is completed.

Roping device with 1 cylinder

Mechanism that, through pneumatic cylinder, creates a bead of film useful to increase the containment and stabilization of the pallet.

Mechanical roping device

Film roping system useful to increase stabilization and containment of the product.

The reel descends from top to bottom thanks to a special electric motor present on the reel carriage.

The height of the film band and the enabling of roping are adjustable through the touch screen control panel.

Top presser

Top presser for the stabilization of light products.

Available in two versions: mechanical and pneumatic.

FILM AUTOMATIC CUTTING

The machine can be equipped with a film cutting device that increase the work efficiency in terms of time and makes the operator’s work easier.

Technical features

| Turntable diameter | mm |

1650 std. 1800 opt. |

| Max load weight | kg | 1500 |

| Turntable speed | rpm | 5÷12 |

| Carriage up-down speed | m/min |

1,5÷5,5 |

| Maximum product dimensions (LxW) | mm |

1000x1200 std. 1200x1200 opt. |

| Maximum product height | mm | 2200 std. 2400/2800/3100 opt. |

| Film carriage type | FR, PDS, PVS | |

| Film stretch | adjustable from panel | |

| Film pre-stretch |

n.a. (FR), fixed 250% std (PDS), variable 150-400% (PVS) |

|

| Forklifting | rear | |

| Power supply voltage | V | 230 V 1Ph |

| Power supply frequency | Hz | 50/60 |

| Installed power | kW |

1,5 (FR) / 1,9 (PDS) / 2,4 (PVS) |

| Max reel dimensions | mm |

500x300 |

| Max reel weight | kg | 20 |

| Film thickness | μm | 17÷35 |

Technical features

| Turntable diameter | mm |

1650 |

| Max load weight | kg | 1500 |

| Turntable speed | rpm | 5÷12 |

| Carriage up-down speed | m/min |

1,5÷5,5 |

| Maximum product dimensions (LxW) | mm |

1000x1200 |

| Maximum product height | mm | 2200 std. 2400 opt. |

| Film carriage type | FR, PDS, PVS | |

| Film stretch | adjustable from panel | |

| Film pre-stretch |

n.a. (FR), fixed 250% std (PDS), variable 150-400% (PVS) |

|

| Forklifting | rear | |

| Power supply voltage | V | 230 V 1Ph |

| Power supply frequency | Hz | 50/60 |

| Installed power | kW |

1,5 (FR) / 1,9 (PDS) / 2,4 (PVS) |

| Max reel dimensions | mm |

500x300 |

| Max reel weight | kg | 20 |

| Film thickness | μm | 17÷35 |