OUR TECHNOLOGICAL SOLUTIONS FOR THE FOOD INDUSTRY ARE THE RESULT OF OUR CONSOLIDATED KNOW-HOW IN ROBOTICS.

The safety and productivity standards of Robopac solutions are recognized throughout the international market, for all types of food products.

Case studies

HEINZ BÉNÉDICTA

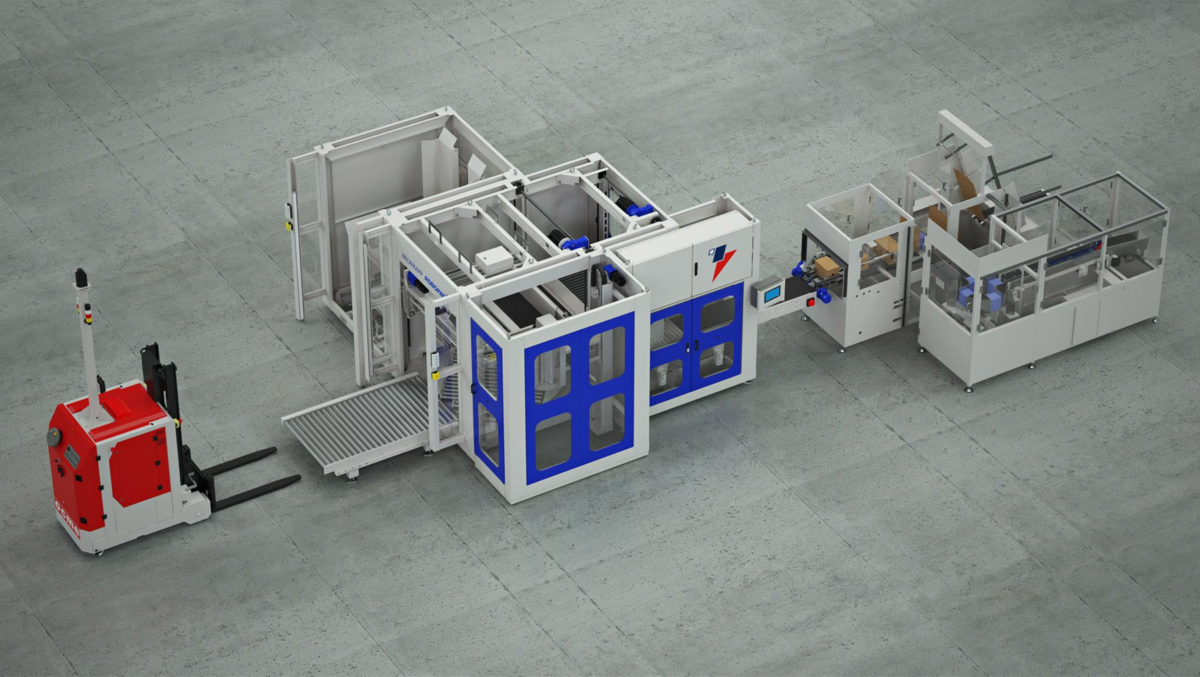

Thanks to the extreme flexibility and ergonomics of its end-of-line solutions, Prasmatic has recently concluded an important project for the Heinz-Bénédicta Group.

Case studies

CONSERVE ITALIA

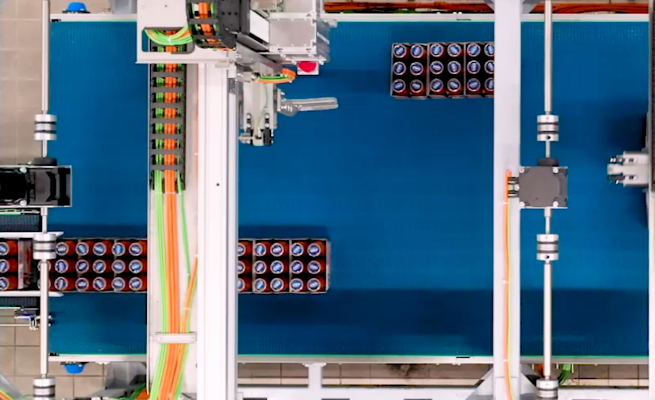

The collaboration between Robopac and Conserve Italia is historical, with actions mainly targeted at the French plants and Pomposa plant - one of the largest food factories in Italy - and aimed at the replacement of individual machines. In 2017 Robopac carried out a more complex project, which was the integration of a TC500 CW for glass bottles containing tomato puree to the already existing line.